Harnessing AI's Power 7 Game-Changing Trends Shaping Manufacturing and Energy

It’s fascinating to watch how quickly the tools we use to build things and generate power are changing. I’ve been tracking the integration of machine intelligence into heavy industry for a while now, and frankly, the pace of adoption in manufacturing and energy feels less like a steady march and more like a sudden, necessary sprint. We're moving past the initial hype cycles where everything was labeled "smart," and now we're seeing tangible, measurable shifts in how factories operate and how grids balance supply. What I find most compelling is that these aren't just software tweaks; they are altering the physics of production and maintenance.

Let’s be clear: this isn't just about better scheduling algorithms anymore. We are talking about systems that can self-diagnose component failure weeks before a human technician would even think to look, or production lines that adjust material flow in real-time based on micro-fluctuations in raw material quality. If you look closely at the shop floor or the remote substation—the places where real work gets done—the change is palpable. I want to break down seven specific areas where this technological shift is truly rewriting the operational rulebook, focusing on what actually works and where the current stumbling blocks remain.

One of the most immediate and quantifiable shifts I observe centers on predictive maintenance and quality control, which now moves beyond simple statistical models. Instead of relying on time-based replacement schedules or waiting for an alarm, current systems ingest continuous data streams—vibration signatures, thermal imaging, acoustic profiles—and build dynamic failure envelopes for specific assets, whether that’s a turbine blade or a CNC spindle. This means maintenance crews aren't just fixing things when they break; they are performing micro-adjustments based on probabilistic assessments of imminent failure risk, often using robotic or augmented reality assistance to execute the repair precisely. Furthermore, in materials processing, this same pattern recognition capability is identifying sub-optimal reactions during polymerization or casting that would have previously resulted in scrapped batches. The feedback loop is now immediate; the process corrects itself before the deviation becomes a defect, leading to yield improvements that were considered theoretical just a few years ago. I’ve seen energy producers reduce unplanned downtime by margins that directly impact quarterly earnings, simply by trusting the machine’s assessment of component health over the operator’s gut feeling. This shift requires a complete overhaul of technician training, moving them from reactive repair specialists to proactive system supervisors who interpret machine advisories. It's less about turning a wrench and more about validating a computational prediction.

Another area seeing radical restructuring involves complex system optimization, particularly in distributed energy resource management and supply chain choreography. Consider the modern power grid, which is no longer a one-way street but a messy network of intermittent solar, battery storage, and traditional generation sources, all needing instantaneous coordination. Machine intelligence is now the central nervous system managing these competing demands, deciding second-by-second where energy should flow to maintain stability while minimizing operational expense. This coordination extends backward into the industrial consumption side, where large manufacturing plants are dynamically shifting energy-intensive tasks—like running massive vacuum pumps or electrolytic processes—to periods when grid prices are lowest or local renewable capture is highest. On the manufacturing floor, this translates to supply chain sequencing that isn't just about inventory levels; it’s about energy cost minimization across the entire production run. If steel prices spike slightly but local solar generation is peaking, the AI might sequence the high-temperature forging step to occur immediately, even if it means slightly reordering the assembly queue. This requires very high-trust interfaces between operational technology (OT) and information technology (IT) systems, which historically have operated in separate, often antagonistic silos. The current challenge isn’t the algorithm’s ability to calculate the optimal path; it’s securing the communication pathways and ensuring the physical machinery responds reliably to these rapid computational commands.

More Posts from specswriter.com:

- →The Science of Rhythm Exploring Meter in Poetry

- →WriteGirl Internships Enhance Technical Writing Skills and Opportunities

- →Florida Gulf Coast Maps Attractions and Essential Travel Facts

- →Venture Capital in 2024 AI and Sustainability Lead Investment Trends as Funding Stabilizes

- →Unraveling the Tangled Web Sheila Carter's Shocking Resurrection Rocks The Bold and the Beautiful

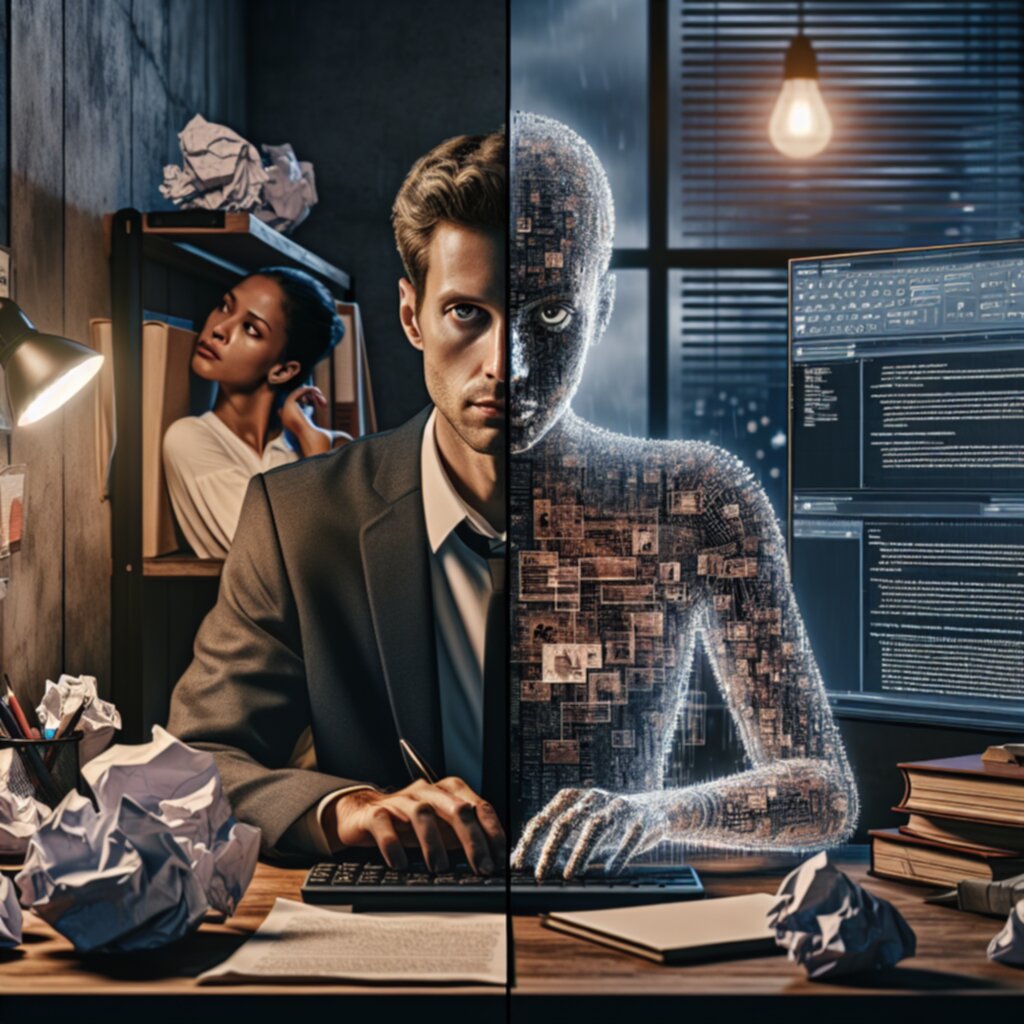

- →AI's Expanding Role Embracing the Human-Machine Partnership in Project Management